Bubble Wrap® Flex (Inflatable Bubble Cushioning System)

- Range of custom accessories available to provide material size and strength flexibility.

- Ultralight materials and recycled content materials offer source-reduction sustainability benefits.

- Heavy-duty materials provide the ultimate in damage protection.

- Inflation speeds up to 90 linear feet per minute.

- On-demand cutting for getting just the right amount of cushioning needed.

- Uninflated, flat base material shipped on rolls for cost-effective shipping and storage.

- Made by Sealed Air®

- Click here for Bubble Wrap® Flex Image Gallery

- Click here to view brochure

-

Call 01795 429501 or email sales@crusaderpackaging.co.uk to discuss.

Description

Bubble Wrap® Flex (Inflatable Bubble Cushioning System)

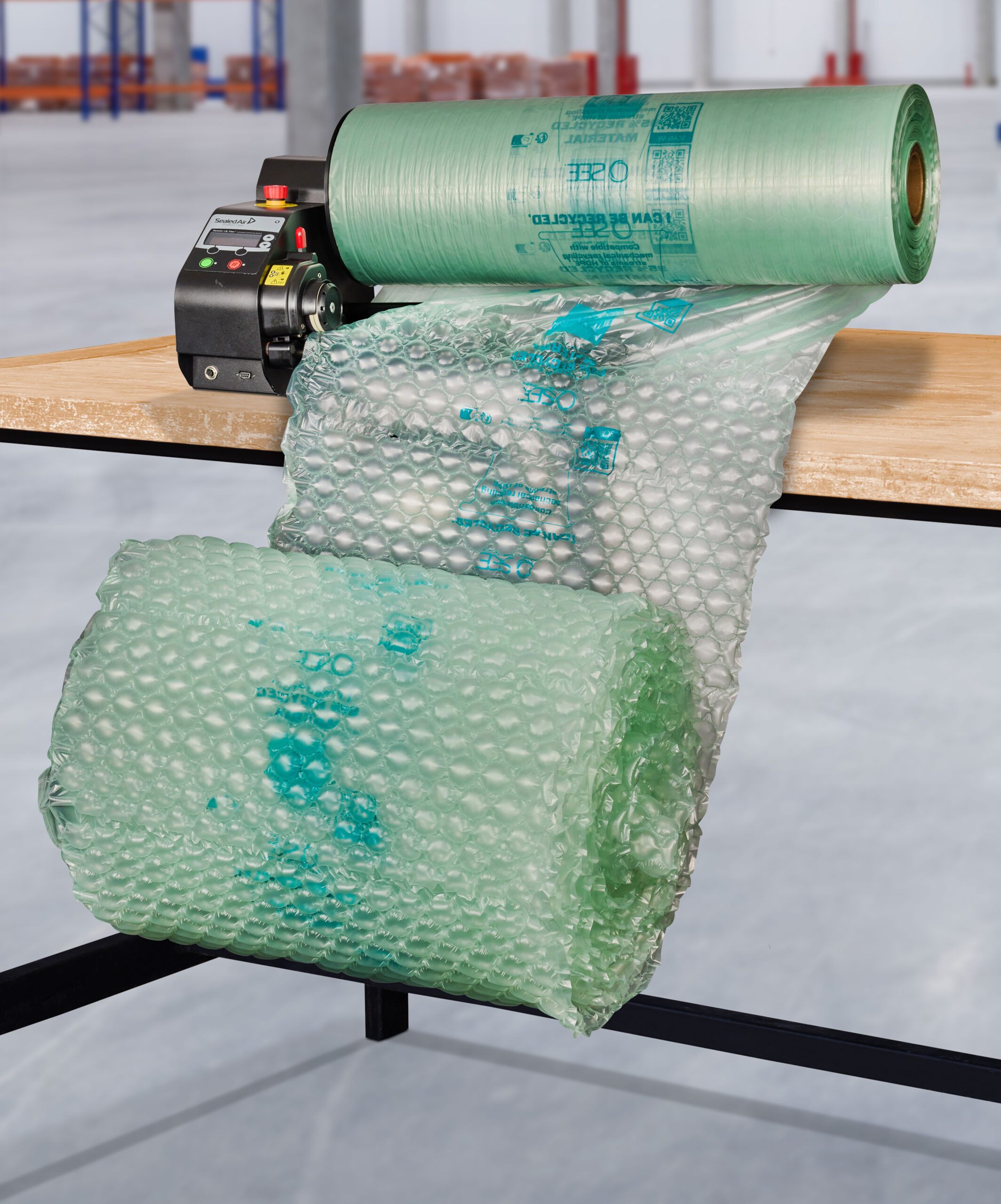

With a range of materials available and an innovative, compact design, our Flex inflatable bubble cushion system provides reliable BUBBLE WRAP® brand protection with the added logistic benefits of on-demand air filling. Whether you’re sending delicate electronics, glassware, or any fragile items, our easy-to-use inflatable bubble cushion systems are perfect for all your packaging needs.

Typical Applications

The BUBBLE WRAP® brand films offer the protective packaging needs from light weight cushioning and wrapping, up to heavy weight cushioning in a variety of markets.

Increased Throughput

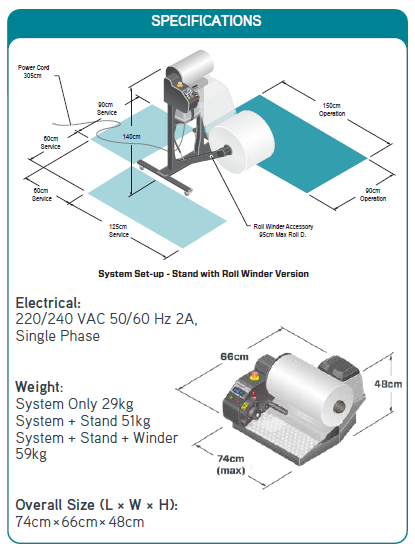

- The BUBBLE WRAP® Flex inflatable cushioning system produces materials at speeds up to 27m per minute.

- Maximum and fast inflation of packaging material with the build in compressor makes manufacturing more productive, operators more efficient and delivers more products out the door on time.

- Throughput is increased as well thanks to long film rolls.

High Reliability

- Delays in production can slow down productivity.

- Limit the potential for throughput loss with the Flex inflatable cushioning system.

- Components are manufactured with high performance materials and coatings for long life system reliability.

System Accessories For Every Configuration

The Flex is supported by a range of accessories to increase the throughput including:

- System stand and roll winder, bins and dispensers for decentralised packaging environments

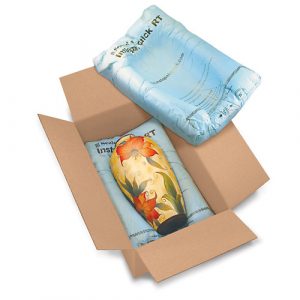

- Instasheeter™ converting system

- Jet Stream Fit® delivery system

Increased Customer Experience

- Attractive, protective, intuitive packages that can be readily reused and are recycle-ready*.

- Multiple film patterns and bubble sizes designed for the right size solution, reducing material usage and improving the packaging process.

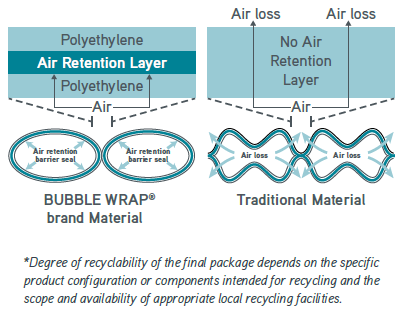

The difference is in the barrier

Sustainability

Maximum inflation reduces excess material and reduces damage

- The system runs with an exclusive range of film solutions. By optimising the right film type for the right application, it is possible to benefit from material reduction.

- A broad material portfolio matches to the system. The material optimises the shipping cycle and outer box size while improving operational efficiency and reducing costs.

- Sealed Air’s patented Barrier Bubble Technology retains the air during the shipping cycle and warehousing. It provides high cushioning performance compared to traditional materials, reducing damage.

- The films are recycle-ready* and contain a minimum 30% Recycled Content diverted from recovered waste. Recycled material contained in BUBBLE WRAP® brand cushioning films is certified according to EN15343 which establishes procedures for track and trace of recycled plastic content sourcing and used in product manufacturing.